Magnetic Tapes – The heart of magnetic measuring technology

The heart of magnetic metrology are the magnetic tapes, which represent the standard of the magnetic measurement technology. They are manufactured at ELGO Batscale AG in Liechtenstein precisely and with the greatest care. With more than 4.000.000 m produced magnetic tape per year ELGO Batscale AG is one of the leading companies in this field.

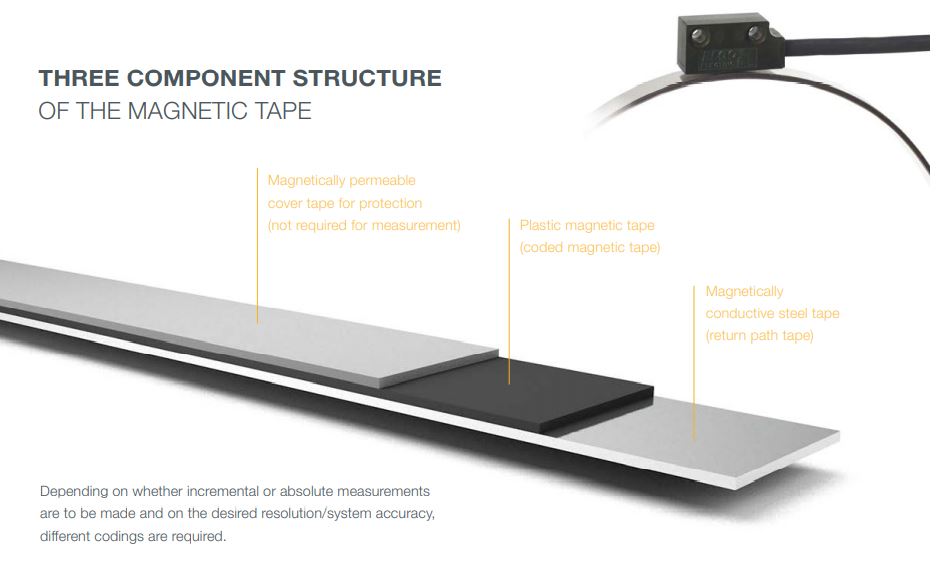

The flexible, bendable tapes consist of a encoded plastic tape, which is connected to a steel tape as a carrier. Thus, by using specially developed processes, one or more magnetic code tracks are applied to the magnetic tapes. The code tracks differ in the pole length. Together with the magnetic sensor, this determines the accuracy and resolution of the measuring system. Ultimately, the know-how consists in creating a very precise magnetic pattern.

Additionally, the magnetic tapes are laid along the distance to be measured by simple adhesive mounting. For incremental measurements the magnetic tape is encoded with regular north and south poles. North and south poles are scanned by a magneto resistive sensor without contact. One sine/cosine signal per pole is generated. These signals are then interpolated and output as square-wave signals. The actual position or the distance covered is determined by counting pulses.

Among other things, the pole length also determines the maximum resolution and accuracy of the measurement. The incremental tapes can be used for almost any measuring length and can be individually assembled.