Summary: From concept to construct, a recent Stenhouse Industries project resulted in an Australian first – a PakTech Can Carrier Applicator machine that can apply PakTech lids at a rate of 200 caps per minute with the Unitronics Vision 1210 PLC + HMI.

Stenhouse Industries, based in Australia’s Gold Coast, specializes in innovative solutions that improve the safety, reliability and productivity of processes. They were given an interesting challenge: to provide the concept, design, and produce a PakTech Can Carrier Applicator machine to be integrated into an existing production line. This machine needed to be safe, reliable, and able to apply Paktek lids at a rate of over 200CPM–able to match the production line rate.

A Unitronics Vision® 1210 PLC + HMI was selected for this job. The built-in 12.1” high resolution screen makes this a preferred model for applications that require a big, clear HMI screen able to supply an advanced user interface. This application needed to be able to support a high-speed output signal of over 4000hz.

Features of the Unitronics Vision® 1210:

- High speed input/output for servo motor position/speed control.

- Modbus RTU for VSD communication/control.

- Modbus TCP for plant integration

- Digital IO for sensor inputs and other motor control.

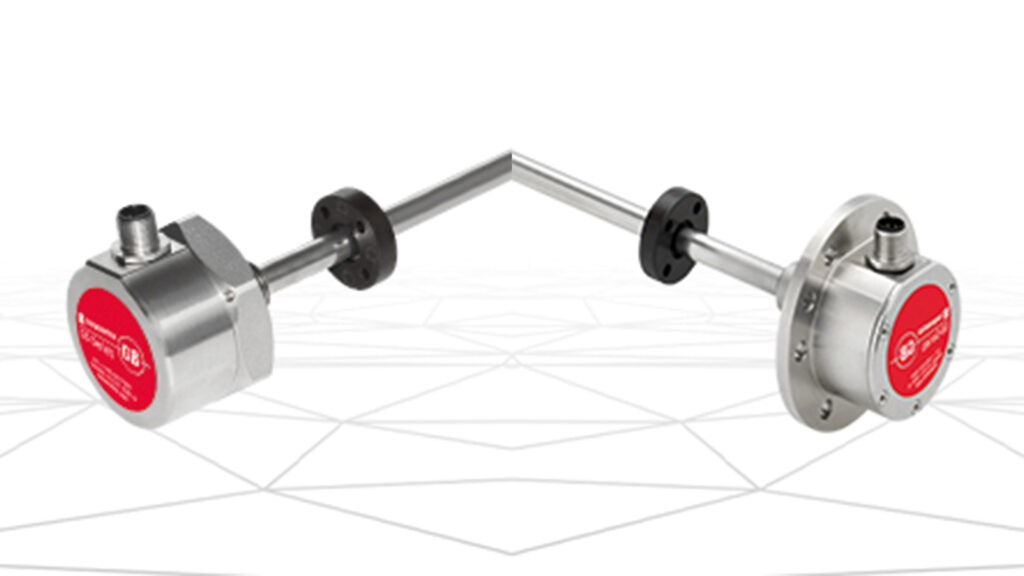

The Stenhouse team found an excellent solution to one control challenge: the use of planetary gearbox’s on the star wheel servo motors required the motors to spin much faster and the high -speed output signal to be increased to over 4000hz to achieve the correct rotational speed of the star wheels.

At that speed, the program scan time could be a limiting factor in detecting the output signal count, which could result in the star wheels being out of position by a few mm each move—obviously an unacceptable event.

This issue was overcome by utilizing the high speed inputs on the PLC to count motor position in conjunction with a fast interrupt routine in VisiLogic, the all-in-one software environment for Vision controllers.

This ensures that the exact position of the servo motors is monitored accurately.

This was not the first time that the Stenhouse team has used Unitronics products. According to the company director Mr Stenhouse:

“Unitronics hardware, in particular the V1210 have been very useful on other projects and I am yet to find any limiting factors with the hardware. Additionally availability during these challenging global times has been good.”

Want to find out more about our Unitronics range? Click here to view online or give us a call on 01344 266530 | [email protected]