Summary: When a nuclear site closes down, an extensive decommissioning and decontamination process begins. This must be done with the utmost care. Tecnubel is a specialist in the field of nuclear decontamination, dismantling of nuclear facilities and contaminated parts, radioactive waste treatment and other nuclear support services. Based in Belgium, Tecnuble developed a decontamination skid specifically for the rinsing of heavily contaminated cells where isotopes Strontium 90 (Sr-90 and Y-90 were treated.

During the time that a nuclear site is in active production, these cells are equipped with an automated supply and discharge system, which is disabled when production stops. The radioactive radiation both inside and around these cells is so high that long-term human intervention is unacceptable. To lower this radiation level sufficiently to allow human intervention, these cells would be decontaminated via the skid.

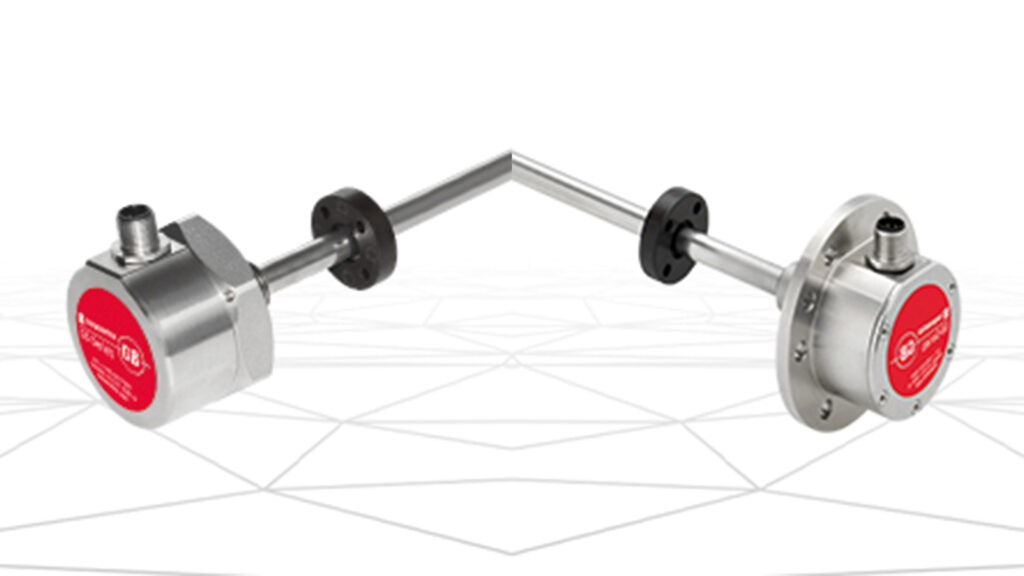

The skid consists of a series of controlled valves, diaphragm pumps, a vacuum pump and a cyclone separator. Together they ensure that the different elements within the cell can be flushed according to specific programs, each adapted to the specifications of the part to be flushed.

Nitric acid solution is flushed through a small opening at the back of the cell. The Strontium present in the cell is thereby dissolved and then pumped out to a shielded vessel for storage and later transport.

Control

For the most current contamination project, Tecnubel has investigated the various possibilities in the field of control. This is how Tecnubel came into contact with Isotron Systems. The Unitronics range was presented on the basis of working demo applications, which soon made it clear that the user-friendly and clear software enabled simple, but certainly also more complex applications to be executed. After various demos and reviewing references from the market, the Unitronics UniStream PLC + HMI was finally chosen. The combination of UniStream PLC, 15-inch color touch screen and 3rd party IO-Link master turned out to be the best option for the decontamination skid.

HMI

The screen with a resolution of 1366×768 pixels with 16M colors (24-bit) is easy to read and gives a clear overview of the entire system.

In this specific application, the screen is placed vertically. By means of the UniLogic software that is fully included in the price, including future updates, the process can be visualized by means of the extensive graphic library.

Programming Environment

UniLogic ™ is the programming environment for both the PLC and the HMI, the variables only need to be created once. In addition, UniLogic has user-defined function blocks (UDFB) that can be easily reused in other projects. The program for cleaning the installations can be easily set via various menus with steps.

Want to find out more about our Unitronics range? Click here to view online or give us a call on 01344 266530 | sales@emolice.com