The LIMAX22 DUE is an absolute magnetic measuring system that offers redundant detection of the car’s absolute position in the elevator shaft. The sensor housing contains two mutually independent sensors with the same function. The functionality of both sensors is recorded and monitored by the elevator system’s master control. With this technology, safety is doubled in such a manner that, in case of failure of one sensor, the other sensor is able to ensure continued operation of the elevator.

Key Features of the LIMAX22:

- For hoisting heights up to 260 m | speeds up to 10 m/s

- Redundant absolute detection of the car position through double sensor

- Resolutions: 62,5 | 125 | 250 | 500 | 1000 µm

- Easy and flexible Installation

- Robust measuring principle, insensitive to dirt, smoke, and humidity

- Interface: CAN basic, others on request

- No referencing necessary

- Easy and flexible to install

- Vertical installation of the magnetic tape

- Wear-free contactless and noiseless measuring principle

Position Measurement:

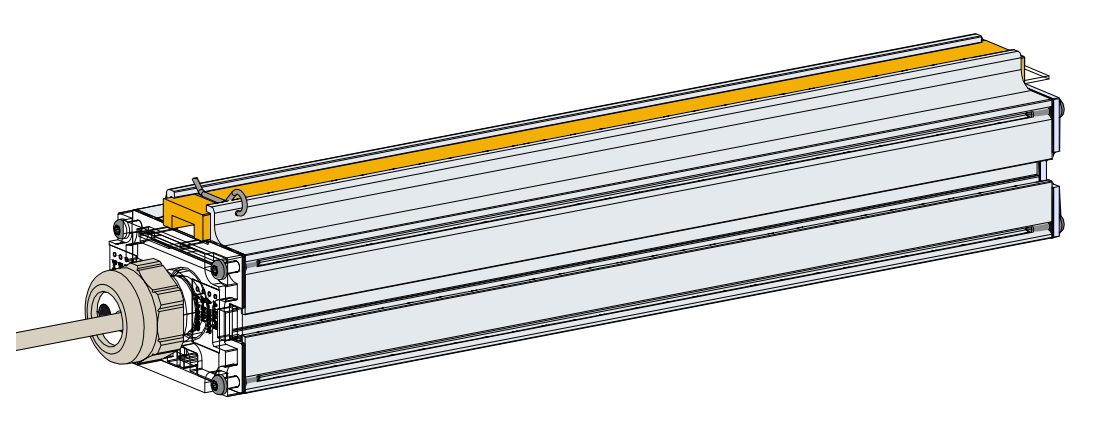

For measurement of the lift position, the dual-sensor which is integrated in alumium profile housing requires an absolute coded magnetic tape (type AB20-80-10-1-R-D-15-BK80), which carries the unique position information as a magnetic code. The magnetic tape is mounted free-hanging in the shaft by using an ELGO mounting set (see accessories on the last page). At the lower end, the tape is tensioned while it is guided along the cabin by a plastic guide on the sensor. The actual measurement resp. scanning is basically contactless. The guidance merely serves to keep the correct distance to the sensor.

Resolution:

Depending on the requirements, an appropriate system resolution can be defined with the order (see type designation). The available standard resolutions are 62.5 / 125 / 250 / 500 and 1000 µm. Interface: For communication with the lift control, a CAN basic interface is standardly used which can optionally be terminated with 120R load resistors (see type designation “T”). Other interfaces as well as customer-specific protocols or CAN device profiles are optionally available on request.

Status LEDs:

The LIMAX22 DUE housing front has for each integrated sensor four separate status LEDs which serve for various messages, e. g. operational readiness or error states of the system, magnetic tape and interface. Connections: By default the LIMAX2 DUE encoder is supplied with a 3 meter long signal cable with open cable ends. Optionally the signal cable can be delivered as plugin version with a RJ45 network cable connector (option RJ45).

Sensor Installation:

In order to mount the sensor to the lift cabin, the mounting angle kit LIMAX2 MW SET can be used, which is available as an ELGO accessory. This mounting kit includes also the required screws with sliding nuts which can be inserted into the mounting groove of the sensor housing in order to fix the angle to the sensor housing. With the remaining long holes, the unit can be fastened on the cabin roof. The tape guidance at the sensor permanently ensures the correct distance between magnetic tape and sensor.

See the LIMAX 22 DUE Flyer here

Emolice is the UK and Ireland exclusive distributor of ELGO Electronic Electric Non-Contact Linear Measurement Systems and Controls, (previously known as ELGO Electric). ELGO Electronic is a German manufacturer that develops and manufactures linear position sensors for manufacturing and lift safety systems.