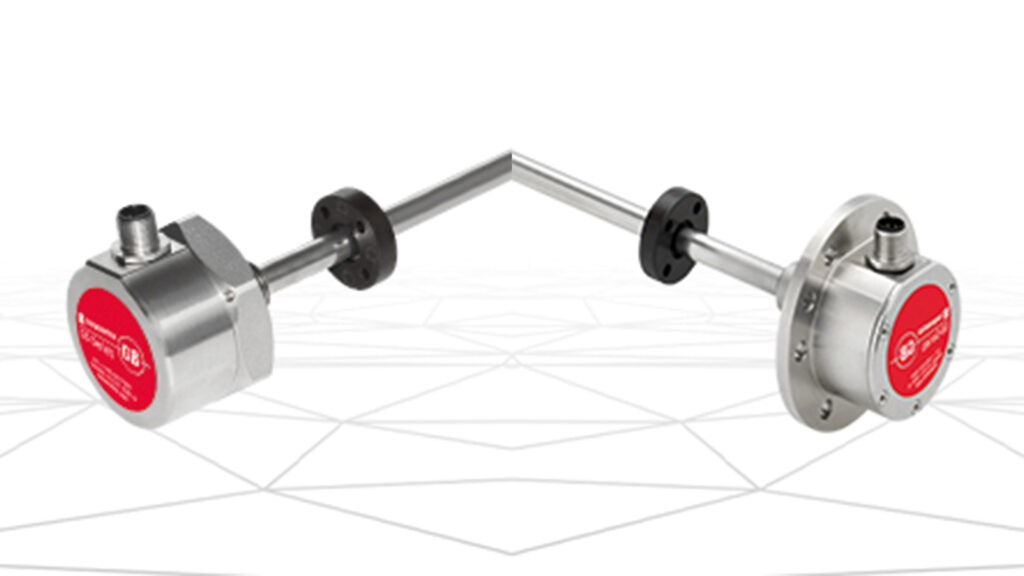

The POSITAL Aluminium Measuring Wheel Encoders are great for precise length measurement of various materials, available with different surfaces such as cross-knurled, smooth, studded and corrugated. Precise wheel and bore concentricity’s (plus optimized wheel mass), combine to produce high measurement accuracy results. Resistance to oils, fuels, ozone and weather influences, plus optimal wear values even under high mechanical pressure, compliments the systems accuracy with the addition of robustness and reliability as well.

The circumference of the measuring wheel and encoder PPR, determine pulses per foot (or meter) of linear travel. The facing material of the measuring wheel and exerted pressure, determine consistent wheel traction. All of these specifications and variables are critical in achieving optimal measurement accuracy.

Whether your measuring wheel encoder application requires velocity or position feedback (or both!) the encoder‘s single turn PPR plays a critical role in overall system performance.

POSITAL‘s programmable encoders bundled with UBIFAST configuration tool enable control system engineers maximum flexibility at time of component selection. The ability to fine-tune PPR ( 1 to 16,384) or change Output Type on-site at time of encoder installation and machine commissioning, can also be the difference between on-time completion or project delay.

POSITAL Measuring Wheel encoders combined with POSITAL digital panel meters can make for a powerful, convenient, cost-effective solution.

Common Applications Include:

▪ Display real-time data to Machine Operator

▪ Control outputs to fi re status alarms

▪ Localized control for conveyor E-stop

▪ Conversion of encoder signal to analog

▪ Serial output for export to Host system

POSITAL DPM’s can be configured for a wide variety of standard encoder output types and simple logic and control function options.

You can view what measuring wheel options Emolice offer here: 10025364 | Measuring Wheel 200mm Smooth PUR Surface – Emolice